HEAVY TRUCK MANUFACTURING FACILITY CASE STUDY

Situation

Customer had T-8 Lights for paint and body inspection in a Heavy Truck manufacturing facility that produces cabs for Peterbilt vehicles. They needed the ability to better see flaws and imperfections.

Opportunity

The Horner Lighting Group proposed an Engineered Tunnel Inspection Lighting system. This product would replace the existing T8 lighting with Horner’s Remote Phosphor Linear Inspection Lighting, commonly referred to as LRPI. This exceptional lighting product allowed an exterior body supplier, who specializes in plastic components, to easily detect any flaws in their manufacturing by providing superior visual acuity as compared to any other lighting product in the market. The system allows their operators to now see flaws that they had a very difficult time seeing in the past.

Solution

The implemented solution yields vastly superior lighting than the previous system, eliminating operator eye strain and allowing the customer to immediately identify any issues, prior to the product moving on to the next process. The supplier is able to dim the system up and down to meet various inspection needs. The installation exceeds their targeted foot-candle requirements, allowing them to meet their customer’s standards. This system has allowed the client to process their product much more efficiently and has eliminated product rework. Their workers are much happier and the company is enjoying the financial savings.

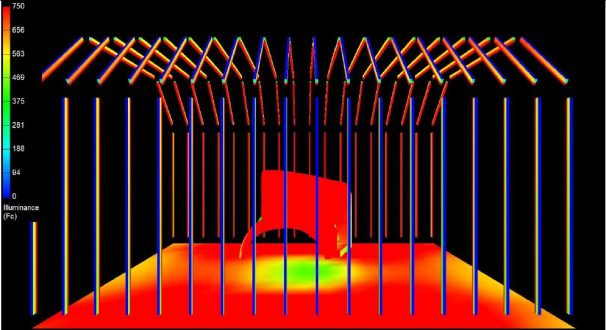

Photometric Example

Lighting Tunnel Sample